Description

Seawater desalination has emerged as a critical solution to global water scarcity, and the efficiency of this process hinges on advanced water purification equipment. Modern desalination plants rely on cutting-edge technologies to transform saltwater into potable water, addressing the growing demand for clean water in arid regions and coastal communities.

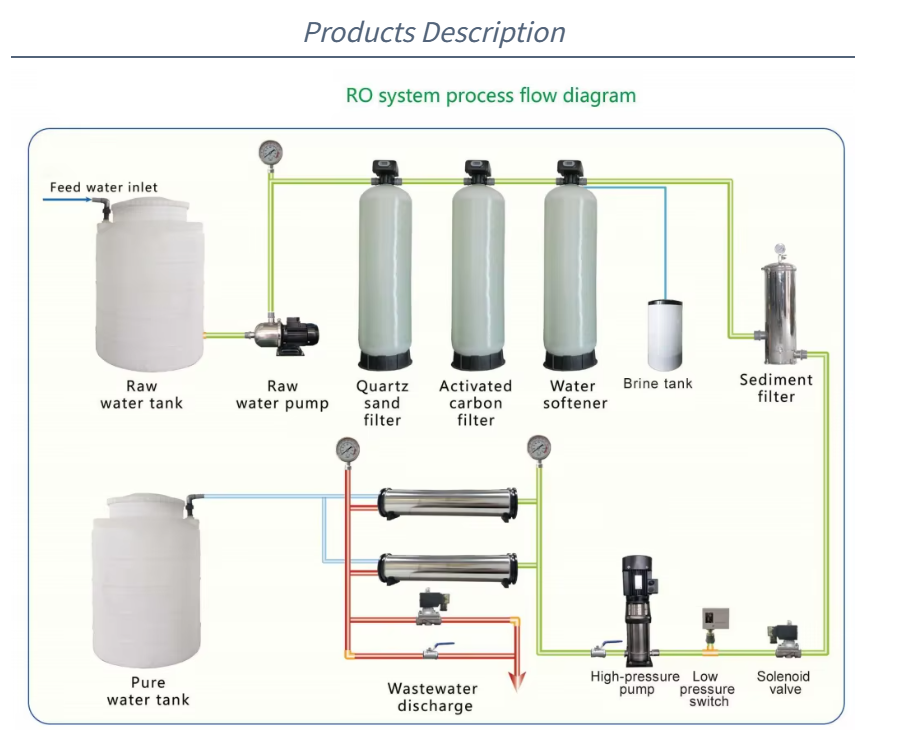

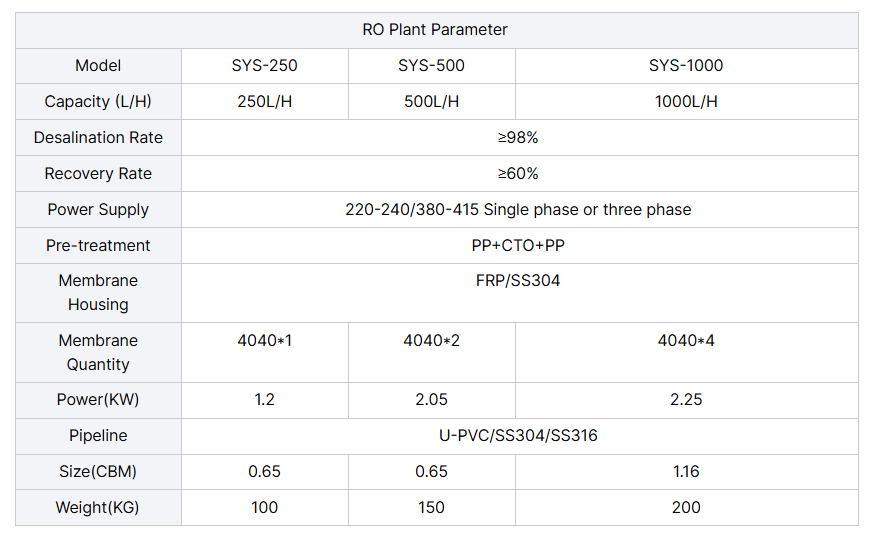

At the core of seawater desalination lies reverse osmosis (RO) systems, the most widely adopted technology today. RO equipment utilizes semipermeable membranes to separate salt and impurities from seawater under high pressure. These membranes, typically made of polyamide thin-film composites, feature nanoscale pores that allow water molecules to pass through while blocking ions, bacteria, and contaminants. To optimize performance, RO systems are paired with pre-treatment stages, such as multimedia filtration and ultrafiltration, which remove suspended solids, colloids, and organic matter. This pre-treatment prevents membrane fouling, extending lifespan and reducing maintenance costs.Another key component is the energy recovery device (ERD), which addresses the high energy consumption of RO processes. ERDs, such as pressure exchangers and turbochargers, capture and reuse the energy from the brine discharge, significantly lowering overall energy requirements. By recycling up to 95% of the hydraulic energy, these devices make desalination more economically viable and environmentally sustainable.

Post-treatment systems are equally vital to ensure water quality and safety. After desalination, water may lack essential minerals like calcium and magnesium, which are critical for human health and pipe corrosion prevention. Mineralization units, using processes like lime softening or controlled CO₂ injection, reintroduce these minerals to meet drinking water standards. Additionally, disinfection methods such as ultraviolet (UV) radiation or chlorination eliminate any remaining pathogens, ensuring the final product is safe for consumption.

Automation and smart monitoring technologies further enhance the efficiency of desalination equipment. Advanced sensors continuously track parameters like pressure, flow rate, salinity, and membrane performance, providing real-time data to operators. Integrated control systems use this data to adjust operations dynamically, optimizing energy use and minimizing downtime. Predictive maintenance algorithms analyze trends to identify potential issues before they escalate, reducing repair costs and ensuring uninterrupted water production.

Sustainability is a driving force in equipment design, with manufacturers focusing on reducing environmental impact. Brine management systems, for example, treat and reuse brine by concentrating it for industrial applications or diluting it before discharge to mitigate ecological harm. Additionally, the use of renewable energy sources, such as solar or wind power, to drive desalination equipment aligns with global efforts to reduce carbon footprints.

In conclusion, the evolution of water purification equipment has revolutionized seawater desalination, making it a reliable and sustainable solution for water scarcity. From high-performance RO membranes and energy recovery devices to smart automation and eco-friendly designs, these technologies work in tandem to deliver clean, safe water efficiently. As global water demand rises, continued innovation in desalination equipment will be pivotal in ensuring water security for future generations.