Dutch Glass Greenhouse Cultivation: Tech - Driven Soilless Growing Methods

The Netherlands has long been a powerhouse in agriculture. A century ago, constrained by limited land, the Dutch began exploring greenhouse technology, evolving from low - rise glass sheds to modern intelligent greenhouses. Today, the country stands as a global leader in greenhouse agriculture.

As early as the 20th century, Dutch agriculture demonstrated strong competitiveness. During World War I, it exported 25 million kilograms of floral products annually. Even amid the severe economic depression in the 1930s, this figure doubled to 50 million kilograms. By 2015, the Netherlands accounted for nearly 60% of the world's flower trade, with bulbous flowers such as tulips making up a striking 85%. Meanwhile, it ranks as the world's largest exporter of tomatoes, onions and seeds. South Holland Province, a hub for greenhouses, undertakes core production tasks.

Currently, the Netherlands boasts over 10,000 hectares of intelligent glass greenhouses. 60% of these are used for flower cultivation, while the remaining 40% focus on fruit and vegetable production, mainly tomatoes, bell peppers and cucumbers. The annual output of tomatoes alone reaches 850 million kilograms, and that of bell peppers hits 360 million kilograms, half of which are red bell peppers. Behind this achievement lies a full set of advanced technologies and standardized processes. The enterprise of bell pepper producer Hans serves as a typical example — after decades of efforts by Hans and his father, it has grown into a top - tier player in the industry.

Core Cultivation Technologies: Soilless Culture & Precision Control

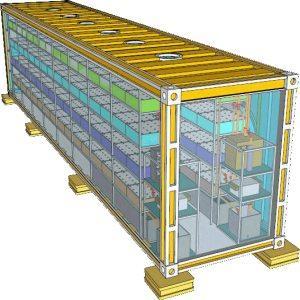

Soilless culture is widely adopted by Dutch horticultural enterprises, among which suspended rockwool cultivation is particularly prevalent. Rockwool growing troughs are hung on the greenhouse frames, crops are planted on rockwool blocks, and nutrient solutions are delivered intermittently through insertion tubes.

The nutrient solution, the core of soilless culture, is meticulously managed. Its daily dosage and supply timing are real - time monitored by professional management systems. This model accelerates crop growth, boosts yields, enhances quality, avoids infestations by soil - borne bacteria and pests, and significantly reduces labor costs.

Green Pest Control & Intelligent Equipment

Chemical pesticides are barely used in these greenhouses. Instead, natural predators like predatory insects and fungi are employed for pest control. Bees are also introduced for natural pollination to ensure the safety of agricultural products.

The greenhouses are equipped with height - adjustable heating pipes, vine hanging systems, logistics trolleys and lifting vehicles. Chain - driven logistics trolleys on the main passages form a closed transport loop, directly conveying harvested crops to the packaging workshops outside the greenhouses. During transportation, bell peppers are automatically weighed and graded. The entire process, from fertilizer transportation to nutrient solution preparation and supply, is fully mechanized without manual intervention.

Additionally, Dutch greenhouses integrate resource - cycling concepts. Water resources are recycled after treatment. Energy - saving technologies such as double - glazed glass and industrial waste heat recovery are applied, which not only cut costs but also minimize environmental impact, truly realizing efficient and sustainable agricultural production.