Greenhouse Ventilation Rate Design: Guidelines and Recommendations

There is no absolute "standard range" for greenhouse ventilation rates, as they need to be dynamically adjusted based on factors such as greenhouse type, crop species, growth stage, and climatic conditions (temperature, humidity, light). The core goal is to maintain a suitable growing environment for crops (e.g., a temperature range of 20-30°C and humidity of 60%-80%, with variations depending on the crop). Below are common reference ranges for different scenarios and key influencing factors, serving as a basis for practical operations.

1. Reference Ranges by Ventilation Method

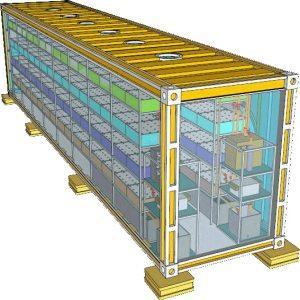

Greenhouse ventilation is mainly divided into natural ventilation and mechanical ventilation (forced ventilation). The two differ significantly in ventilation rate, and the choice should align with crop requirements. Specific parameters are shown in the table below:

|

Ventilation Method |

Common Ventilation Rate Range (Air Exchanges per Hour, times/h) |

Applicable Scenarios |

Key Features |

|

Natural Ventilation |

1-5 times/h (typically 2-3 times/h for daily use) |

1. Temperate regions or mild climates in spring and autumn 2. Crops with low heat requirements (e.g., leafy vegetables, strawberries) 3. Growing scenarios with low demand for ventilation stability |

1. Relies on natural wind speed and direction, with no additional energy consumption 2. Ventilation efficiency is highly affected by weather, resulting in low stability 3. Effectiveness can be improved by increasing the area of roof vents and side vents |

|

Mechanical Ventilation |

5-15 times/h (can be increased to 20 times/h in high-temperature and high-humidity conditions) |

1. Tropical/subtropical regions or high-temperature environments in summer 2. Crops with high heat requirements (e.g., tomatoes, cucumbers, flowers) 3. Scenarios in winter requiring humidity control while minimizing heat loss |

1. High ventilation efficiency and strong stability, allowing for precise regulation 2. Requires matching fan power and air inlet area, with certain energy consumption 3. Suitable for growing crops sensitive to environmental conditions |

2. Key References by Crop Type

Different crops vary in sensitivity to temperature, humidity, and CO₂ concentration, which directly determines the lower and upper limits of ventilation rates. Adjustments should be made dynamically based on crop species and growth stages:

· Leafy vegetables (lettuce, spinach, etc.): Low ventilation demand, with rates usually controlled at 2-6 times/h. The priority is to prevent downy mildew caused by excessive humidity; rates can be appropriately increased to 5-8 times/h during high-temperature summers.

· Fruiting vegetables (tomatoes, cucumbers, peppers, etc.): Moderate to high ventilation demand. Rates are 4-10 times/h during the growth period; enhanced ventilation (6-12 times/h) is required during the fruiting period to reduce high temperatures in the greenhouse (preventing temperatures exceeding 35°C, which affects fruit set) and humidity (reducing gray mold and powdery mildew).

· Flowers (roses, lilies, etc.): Highly sensitive crops requiring precise ventilation rate control, typically 3-8 times/h. It is necessary to avoid excessive ventilation (which causes leaf water loss) and insufficient ventilation (which triggers diseases); rates can be appropriately reduced to 3-5 times/h during the flowering period to stabilize the environment.

· Seedlings: Seedlings have weak stress resistance, so ventilation rates should be low (1-3 times/h). Avoid direct cold wind (which causes frost damage or water loss), and focus on adjusting temperature and humidity gradually (e.g., increasing rates from 1 time/h to 3 times/h step by step).

3. Adjustment Principles for Special Climatic Conditions

· High-temperature summers (greenhouse temperature > 32°C): Increase ventilation rates to cool down quickly. Mechanical ventilation can be raised to 10-15 times/h; for natural ventilation, use sunshade nets (to reduce heat absorption from sunlight) and fully open roof and side vents. If evaporative cooling pads are used, rates can be appropriately reduced to 8-12 times/h to prevent excessive humidity.

· Low-temperature winters (greenhouse temperature < 15°C): Lower ventilation rates (0.5-2 times/h for natural ventilation, 1-3 times/h for mechanical ventilation). Prioritize "short-duration, small-scale ventilation" (e.g., ventilating for 10-20 minutes at noon daily) to avoid excessive heat loss, while reducing humidity (to prevent condensation-induced diseases).

· High-humidity weather (e.g., rainy days, hazy days): Increase ventilation rates by 20%-30% compared to normal conditions (e.g., raising natural ventilation from 2 times/h to 2.5-3 times/h). Prioritize mechanical ventilation (to avoid introducing external moisture via natural ventilation) and use in-greenhouse dehumidification equipment (e.g., dehumidifiers, quicklime) to prevent excessive crop growth or diseases.

4. Notes

1. No "absolute standards"—rely on crop feedback: If crops show signs such as leaf curling (high temperature), water droplets on leaves (high humidity), or reduced flowering/fruiting (unsuitable environment), adjust ventilation rates promptly instead of strictly following fixed ranges.

2. Adjust in conjunction with CO₂ supplementation: If artificial CO₂ supplementation is used in the greenhouse (e.g., high CO₂ levels are required for tomatoes during the fruiting period), reduce ventilation rates appropriately (to prevent CO₂ loss). Typically, control mechanical ventilation at 3-5 times/h and natural ventilation at 1-2 times/h, while monitoring CO₂ concentration (maintaining 800-1200 ppm)

If your project requires efficient greenhouse solutions or you wish to learn about the latest application cases of greenhouse technology, please feel free to contact us. Our team will provide end-to-end support—from solution design and equipment selection to project implementation—based on your planting needs and site conditions, helping improve the quality and efficiency of your agricultural production. We look forward to exploring more possibilities of modern greenhouse cultivation with you. Contact us: [Number/Email/Website Link].